East Asia is experienced in flexible packaging industry for over 2 decades. With our GMP-certified sterile workshop, we ensure the entire production process from material handling and manufacturing through to quality inspection and product delivering under strict control. We are able to produce both die-cut lidding and rollstock lidding satisfying the requirements of every customer.

We apply food grade 8011/8079 aluminum foil to manufacture our lidding foils. The 8011/8079 aluminum foil is innocuous and odourless, offering good air-impermeability and wear-resistance, when laminated with paper and plastic, good strength and heat-sealing performance are obtained. Therefore, our aluminum lidding foil provides great protection against water vapor, air, ultraviolet and germ.

All our raw materials are purchased from well-known aluminum suppliers such as CHALCO, strict quality control processes are already conducted before delivery to our factory. We’ll also perform quality inspection on incoming materials to make 100% sure they are qualified. We can also do FDA or ISO standard inspection upon customer’s request, and provide certificate if inspection from third-party institute.

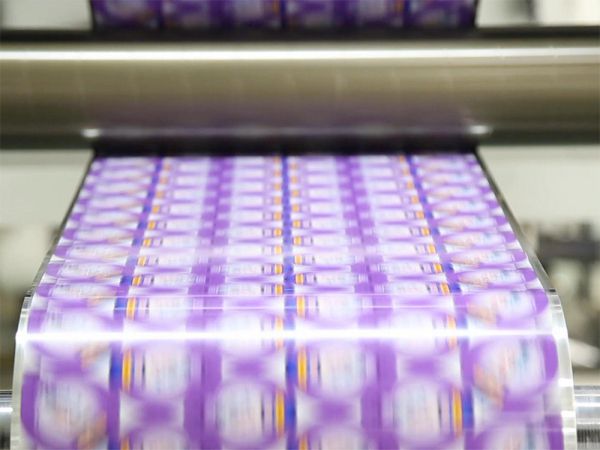

Our printing workshop is equipped with 2 fully automatic high-speed gravure printing presses (HYA10-650B 10-color printing machine). With computer-controlled automatic color registration, the printing process is accomplished at high speed with accurate color registration and elegant pattern, giving your product a superior look. The printed lidding foil is then sterilized at 180℃ to ensure food grade safety.

The laminating workshop has 2 fully automatic laminators (HGF-650 high speed dry lamination machine). After lamination, the lidding foil will go through a curing process at 150℃. With laser positioning techniques and high-quality glue imported from Korea, paper, plastic and aluminum foil are tightly and precisely laminated together, good durability and eco-friendliness are achieved.

After curing and sterilizing at high temperature, deformation and wrinkle are avoided, while the lidding foil is non-toxic and corrosive.

East Asia has 10 embossing die cutters, which are able to create die-cut aluminum foil lids with smooth edges and surfaces. High production capacity guarantees that die-cut lidding products are delivered on short timelines.

Over 100 dies with diameters from 26mm to 133mm are available to manufacture die-cut lids with customer-specific sizes. Dies with different shapes such as "V" tab, "U" tab, round, square and triangle are also ready to serve. If you have special needs, we can also develop new dies to fit your requirements.

Our professional team will conduct quality inspections on sizes, thickness, curing quality, printing quality of finished lidding foil products, and remove the unqualified ones to ensure only qualified die-cut lidding or rollstock lidding foils are delivered to our customers.

We have established a new testing lab with professional and advanced equipment in early 2018, our quality control ability is therefore promoted to a new level. We’ll send our lidding foils for overall tests in authorized institutes, and make sure they meet industrial and international standards.

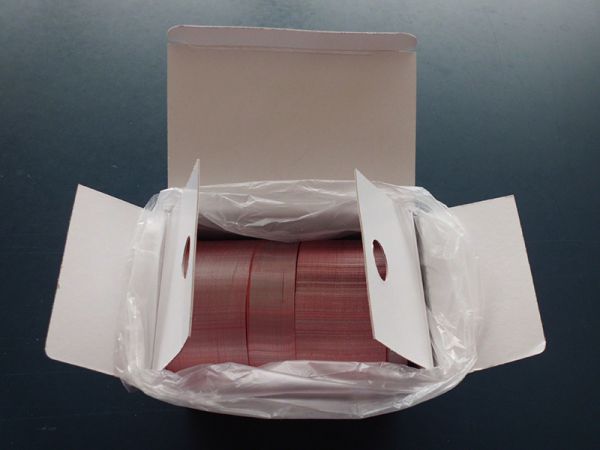

Die cut lids

Usually 1000 die cut lids per box, 18 boxes per carton (customized size).

Rollstock lidding foils

A lidding foil roll is wrapped with plastic film for protection, and 3 rolls are packed in a carton. Carton size depends on the roll size as per customer request.